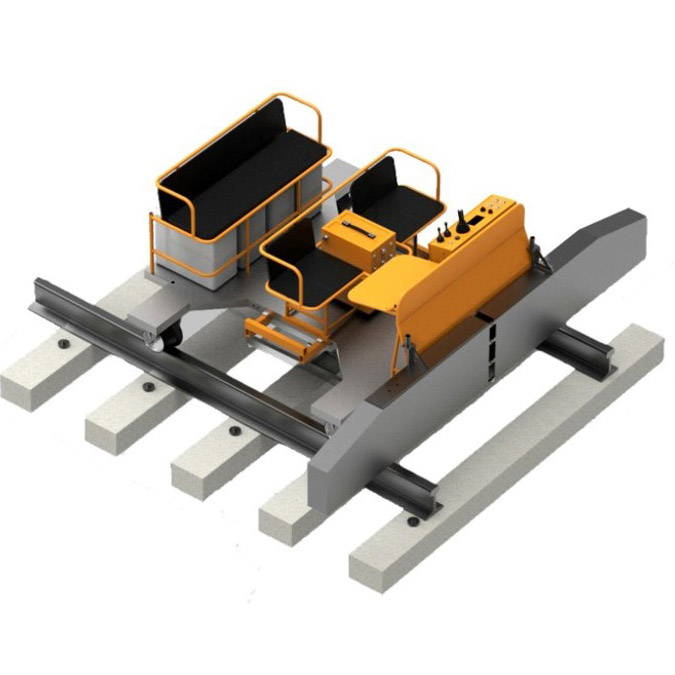

The RS-20 integrated rail state inspection vehicle can integrate the ultrasonic system to scan the rail image, which can well assist the playback person to complete the judgment of the flaw detector, and can also automatically identify the abnormal conditions on the track surface and both sides of the track.

Main Specifications:

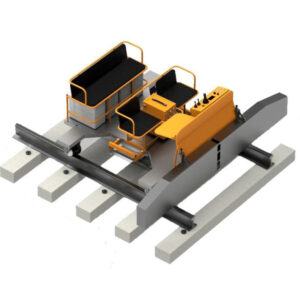

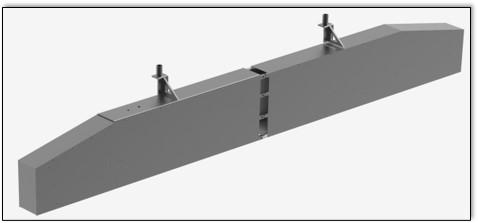

Assembled size: 1800*1800*900mm

Total assembled weight: 131kg (single module weight<48kg)

Assembly time: <5 min (4 persons)

Slope capacity: Maxim 35‰

Motor power: 1200W

Endurance: 60KM or 4 hours

Maxim running speed: 20Km/h

Speed cruise: included

Mileage accuracy: 1‰

Parking slope: <35‰ (with water tank)

Battery protection system including several features like, system over current, over pressure, under pressure, short circuit and other protection.

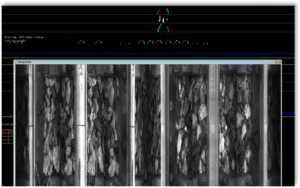

RS-20 integrated rail state inspection vehicle contains hardware and software parts. Hardware part main parts track monitoring image acquisition box, and software part includes, track image collection control software and image playback software (including automatic identification).

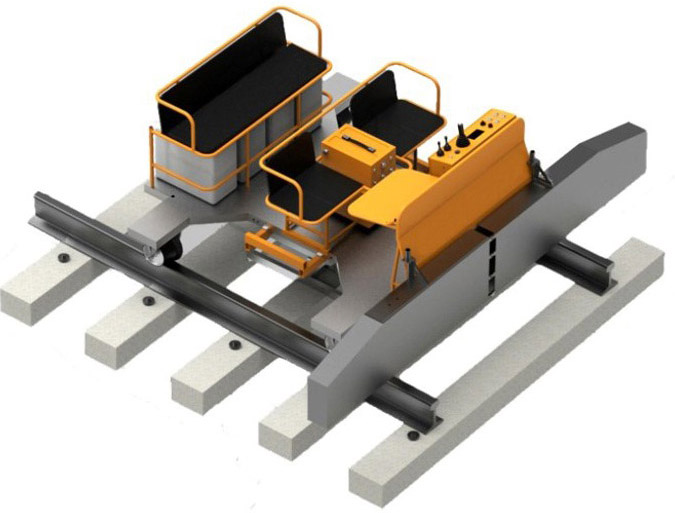

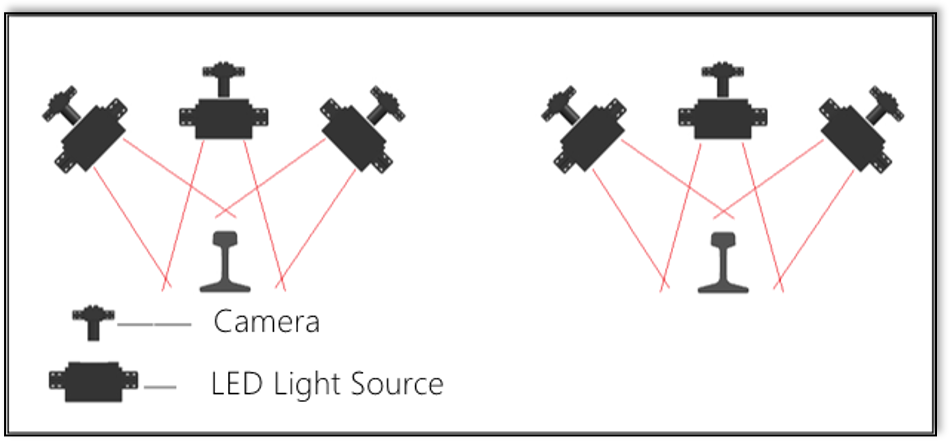

There is also image collection box for the rail monitoring system, and the camera array takes the rail images from 3 different angles. The camera uses a wire-array camera for collection, so the collected image does not deform and provide a guarantee for the subsequent image processing.

Rail Monitoring System

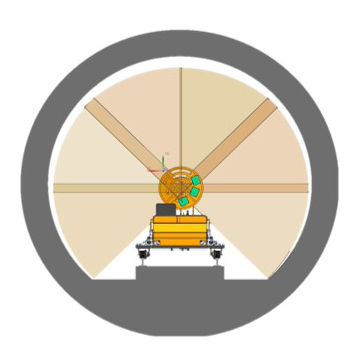

Rail Bed Patrolling System

It is composed of hardware parts and software parts, it is very important function of rs-20 integrated rail state inspection vehicle, and the main part of the hardware is the tunnel detection image collection box, which is responsible for the overall channel bed image collection. The software part includes, tunnel image collection and control software, tunnel image data analysis software, and also tunnel inspection data management system.