Japanese Railway

Japanese mostly produce the railway flaw detection vehicles by themselves, only import small part from Australia. The flaw detection vehicle body adopts special railway vehicles, and the detection speed is 30 ~ 40km/h. The Japanese flaw detection vehicle has dual functions of flaw detection and rail shape measurement (measuring wear, etc.). The company producing the flaw detection vehicle is tokimec (Tokyo gauge) company, which adopts sliding shoe ultrasonic sensor with detection speed of 40km/h, and has been used in Shinkansen and other lines. The flaw detection vehicle imported from GEMCO company in Australia adopts wheel sensor, and the maximum detection speed is 33km/h. The average annual testing mileage of a single vehicle is about 5000km.

Development track of Chinese rail flaw detection vehicle

China has tried to introduce large rail flaw detection vehicles since 1989. China import first flaw detection vehicle from Australia GEMCO company. The vehicle failed to meet the technical indicators required by the contract. Since 1993, Pandrol Jackson compnay introduced their SYS-1000 flaw detection vehicle.

In recent years, Sperry company has newly developed the 1900 type detection system for China’s railway. In terms of acoustic design, it draws lessons from the technical characteristics of China’s railway small rail flaw detector, then adds an ultrasonic probe with deflection of 70°, so that it improve the detection ability of rail head core damage; The diameter of the probe wheel get bigger from 6.5 inches to 9 inches. So the large wheel reduce the internal sound path of the ultrasonic wheel. Since 2000, the application of China’s railway flaw detection vehicles has become more and more mature. According to the statistical data of 2010, the total flaw detection mileage of the whole road is 283,600 km, the average annual detection mileage of single vehicle is more than 10000 km, and the operation efficiency is much higher than that of European and American Railways.

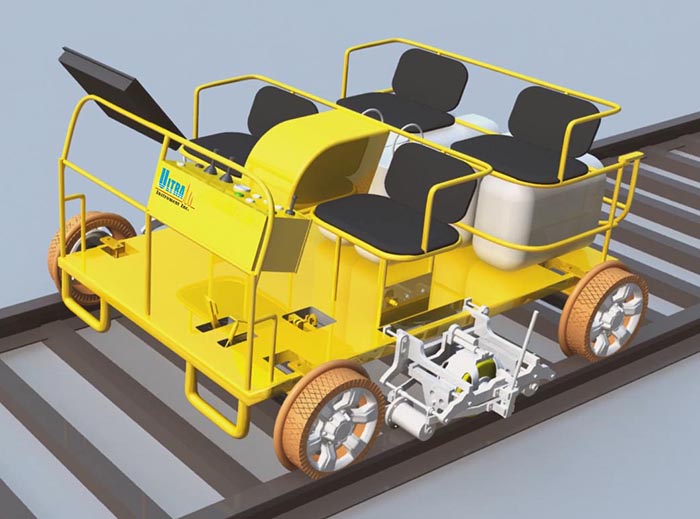

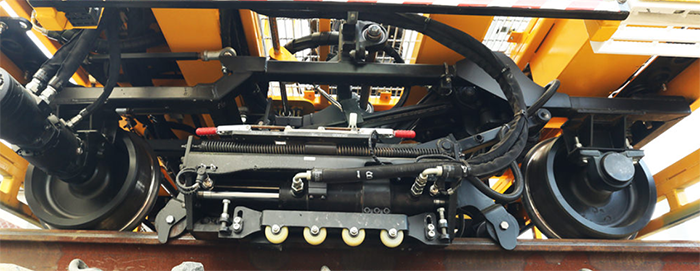

Development of New Model Double Rail Flaw Detection Vechile

Around 2010, Ultra Instrument Inc developed the dual rail electric type ultrasonic flaw detection vehicle UR18-D in combination with the actual needs of the Chinese market. The vehicle is driven by lithium battery and equipped with four walking wheels. Mean while, the product has characters of better price-to-cost ratio, more practical and economical. It can detect the dual rail in real time at the same time, and all data can be stored and played back. After passing the official inspection and certification of China’s railway department, the market share of the product has reached more than 75%.