Analysis of Effective Ways to Improve the Quality of Rail Flaw Detection

First, it is necessary to establish and improve the leading organization. The special principals of relevant departments should do a good job in rail flaw detection, establish rail flaw detection workshops in each track maintenance section, or track maintenance machinery section, and equip certain engineering and technical personnel for rail flaw detection. The superior leaders also need to actively participate in the on-site rail flaw detection, and deeply understand the work of rail flaw detection, And solve the problems in rail flaw detection in time.

Second, establish the inspection, maintenance and repair center of rail flaw detection instruments to carry out irregular and regular inspection of rail flaw detection equipment in each section. Annual inspection is essential. So as to ensure the good operation of rail flaw detection instruments, and equipment and promote the rail flaw detection work to be carried out more smoothly.

Third, we should strictly implement the development and implementation of various rules and regulations, irregularly inspect various statements, work records, daily instrument and equipment maintenance, and strictly assess and evaluate, we should do a good job in the training and education of rail flaw detection personnel, constantly improve their understanding, strengthen their sense of post responsibility,

Fourth, in different seasons, the climate characteristics and rail damage prone sections, the rail flaw detection cycle is more reasonable and scientific. Generally, the winter is five months, which requires abnormalities on bridges, tunnels, small radius curves, large ramps, sections with poor rail status and the number of damaged rails, The inspection cycle of fatigue damage (such as nuclear damage, fish scale damage, screw hole crack, horizontal crack, etc.) found in two consecutive flaw detection cycles shall be shortened, so as to realize your leakage and prevention and avoid the occurrence of missed inspection.

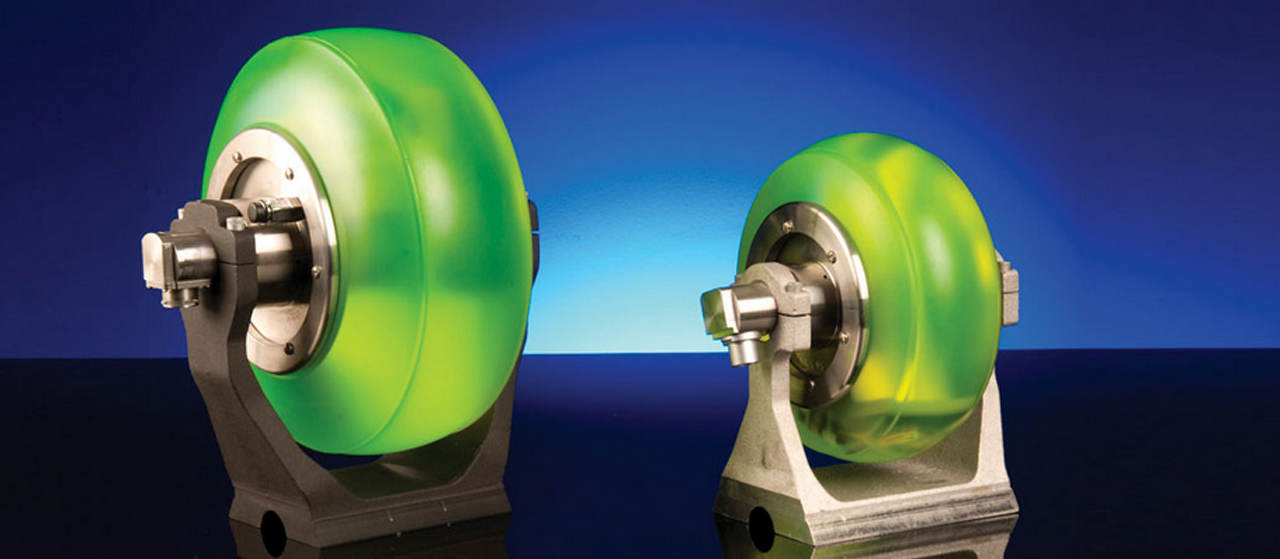

wheel probe detection technology

Fifth, we should strengthen the management of three-level data playback, make full use of the playback function of digital flaw detector to play back the data, and eliminate some injuries endangering driving safety in the bud in time. In addition, we should also do a good job in recording all kinds of rail damage, the monitoring of slightly damaged rail can not be ignored, collect and integrate data, and analyze the rail flaw detection, so as to find the general law of rail flaw detection.