Function Introduction

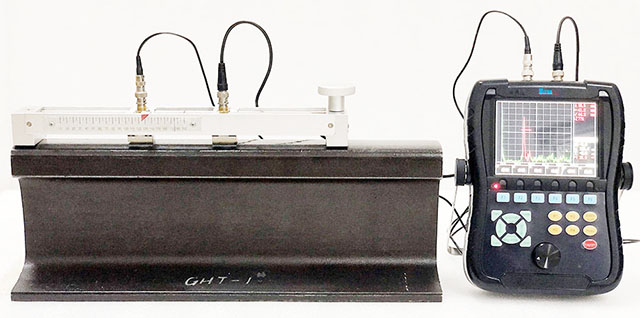

Firstly, the ultrasonic rail flaw detector adopt advanced square wave excitation technology, with stable performance, light and portable, convenient operation and high cost performance. The display adopts high-resolution TFT screen (640×480), fully competent to work outdoors and in direct sunlight; High-performance lithium battery that can work continuously for up to 8~11 hours, with a weight of only 1.5kg. In a words, tt is especially suitable for use in the NDT operation site of railway,metallurgy.

Main Characteristic of Ultrasonic Rail Flaw Detector

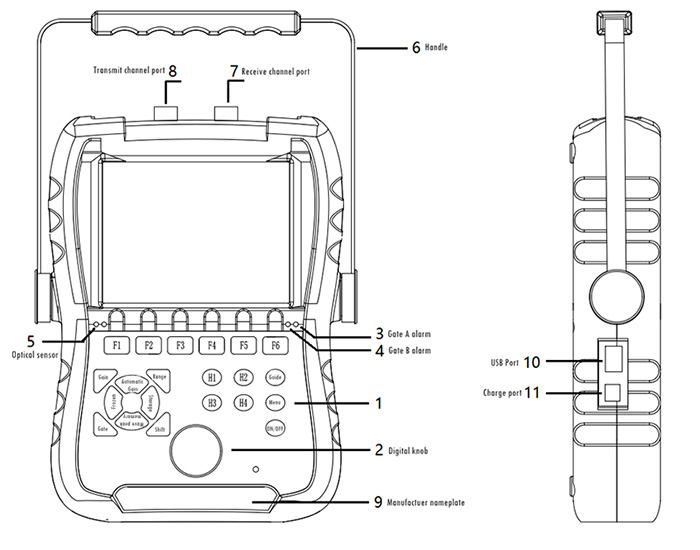

- Multifunctional shortcut key design, so that, users can customize the function of the key to facilitate operation habits. In conclusion, the shortcut key function covers almost all functions in the instrument.

- It can realize the continuous storage function of on-site waveform for more than 50 hours, and the recording of dynamic data can most directly reflect the on-site detection state. Data playback management can be carried out through professional data playback management software

- Preset flaw detection report record form, including welding head number, operation time, operator, weld mileage position, line name, line type, line type as well as strand type, etc. Moreover, the on-site flaw detection data are complete and clear.

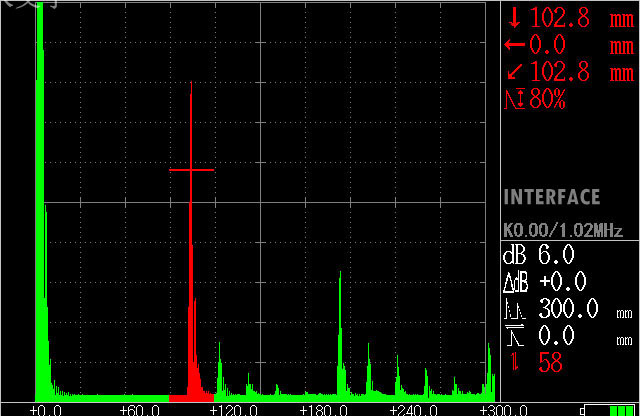

- There are advanced circuit design and the most advanced ZYNQ hardware architecture, so the echo signal of defects can be displayed and analyzed quickly and accurately, while the changes and details of various weak and small signals can be responded in time. Moreover, the real-time and authenticity of the echo signal can be effectively guaranteed.

- Firstly, advanced square wave excitation technology has excellent penetration and signal-to-noise ratio for detecting high attenuation materials or thick workpieces; Secondly, the adjustable excitation pulse width, excitation voltage and damping resistance make it possible to detect thin workpieces and composites with high resolution.

- Firstly, Automatically calibrate material sound velocity, secondly, probe delay and probe K value; Finally, convenient DAC curve making and application.

- External USB flash disk can be connected to realize communication with computer and data transfer.

- Ergonomically optimized structure and appearance, with multi angle adjustable handle, in addition, the CK2108 handheld ultrasonic rail flaw detector weighing only about 1.5kg, including battery and charger, which is very convenient to operate and carry.

Main Specifications

- Transmit pulse: – 50V ~ – 250V negative square wave continuously adjustable, 25V step. The pulse width is continuously adjustable from 30ns to 1000ns in steps of 5ns.

- Working mode: single and double.

- Damping: 80 Ω, 400 Ω.

- Operating frequency: 0.8mhz ~ 10MHz, divided into broadband and narrowband.

- Gain range: 0.0~110.0db. Step value: 0.1dB, 1.0db, 2.0db, 6.0db.

- Sound velocity range: 1000m/s ~ 15000m/s, continuously adjustable, built-in sound velocity of 30 common materials.

- Detection mode: positive, negative, full wave, RF.

- Alarm: two hardware driven real-time alarm signals, optional: incoming wave alarm, loss of wave alarm, DAC curve alarm, alarm mode optional buzzer and led.

- Display screen: 5.7-inch 640×480 highlight display screen.

- Repetition frequency: 25Hz, 50Hz, 100Hz, 200Hz, 400Hz, 800Hz, automatic, manual mode.

- Vertical linearity error: ≤ 3.0%.

- Horizontal linearity error: ≤ 0.4%.

- Sensitivity margin: > 60dB.

- Resolution: > 26dB.

- Dynamic range: ≥ 32dB.

- Inhibition: 0% ~ 99%.

- Attenuator accuracy: every 12dB <± 1dB.

- Interface: USB host q9x2.

- Ambient temperature: – 30 ℃~50 ℃ (-22°F~122°F)

- Relative humidity: (20 ~ 95)% RH.

- Weight: 1.5kg