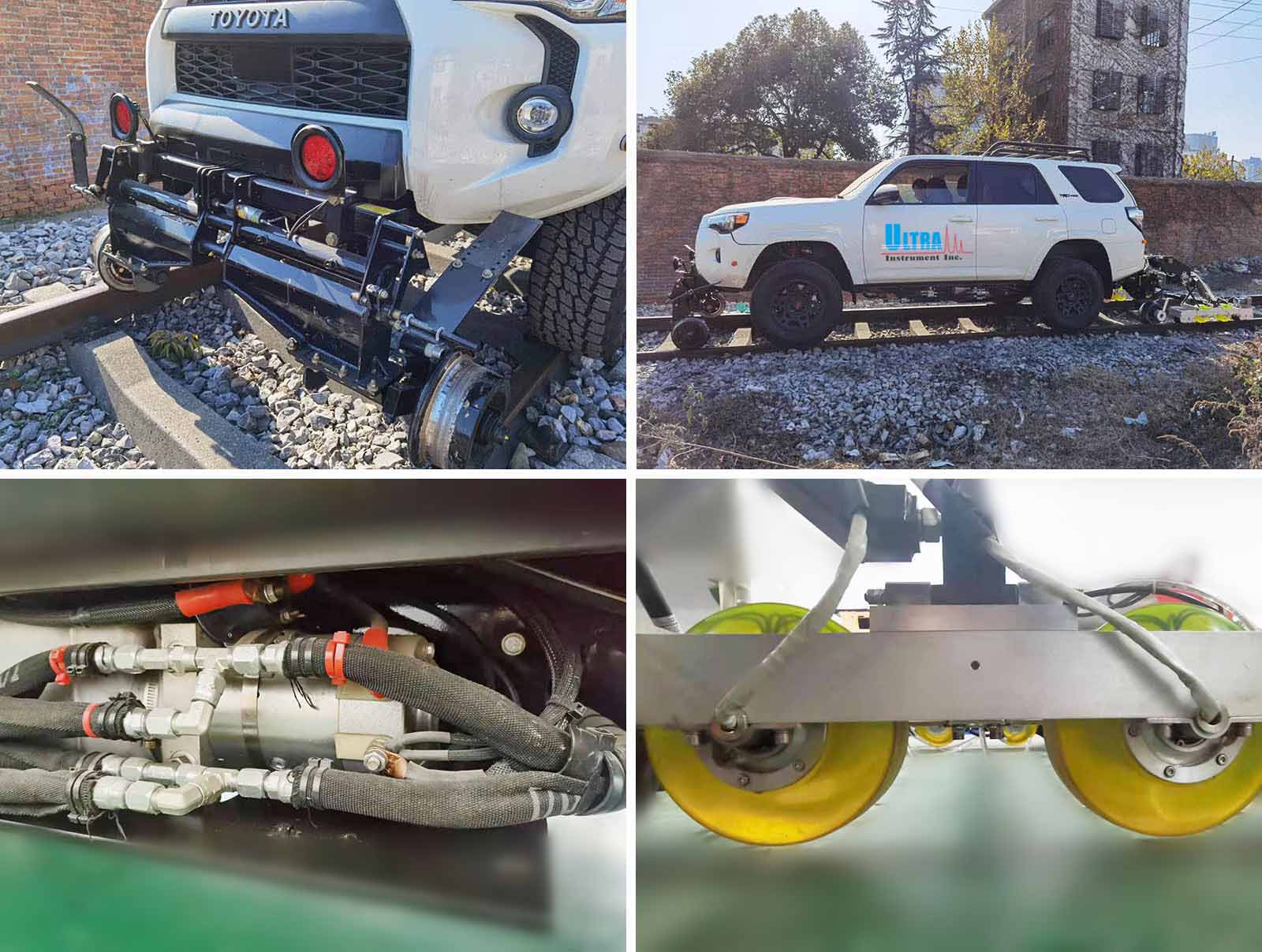

GT6600 Hi-Rail Ultrasonic Flaw Detection Vehicle

With the development of the high speed train in the world, even the existing train’s speed are increasing to 200km/h, the operation of traditional hand push cart brings a lot of risks for operator’s safety, the railroad decide to use maintenance window to do the rail flaw detection operation, and not allow the detection during the short interval of the trains, in this situation, the traditional hand push cart is very difficult to finish the inspection of a typical station interval of 30km within 120~180 maintenance timing window. Therefore, the market demand for high-speed detection equipment is higher and higher, our GT6600 had been successfully developed and put into production in such background.

The GT6600 ultrasonic hi-rail flaw detection vehicle provides a comprehensive and thorough rail testing platform for international customers, equipped with the latest wheel probe, it can achieve the highest standard of railway testing safety and accuracy.

Main detection specifications:

-

Testing rail type: 43kg ~ 75kg/m

-

Operating temperature: – 30°C ~ 45°C(-22°F~113°F)

-

Number of wheel probes : 2 * 10pcs

-

Display mode: A/B scan (B scan real-time display)

-

Probe frequency: 2 ~ 4MHz

-

Trigger pulse: 520v negative pulse

-

Gain range: 0 ~ 72db

-

Data storage: 300km (adjustable)

-

Mileage error: ≤ 2 ‰

-

Water tank volume: 400L

Main vehicle specifications (refer to the vehicle manual)

-

Vehicle type: 4WD SUV

-

Engine volume: 3.0L

-

Transmission type: Manual

-

Maxim detection speed: 40km/h

-

Rail test endurance (based on 40km/h): 10h

-

Road driving range: (60km/h): 6h

Innovation Gallery

innovation gallery of gt6600 hi-rail gt6600 rail flaw detection vehicle