GJY-H-CK-22CM Track Geometry Measurement

Driven by an electric flaw detection vehicle, the track geometry measurement system runs at a maximum speed of 15km/h while conducting geometric dimension inspection of the double rail track. The testing items include: track gauge, left and right track direction, left and right height, cant (superelevation), twist, gauge change rate, left and right versine, rail wear, and mileage error less than 1 m/km. It has fast detection speed, high accuracy, online analysis and processing, diversified report output, and easy software operation.

Meet accuracy requirement of Level I track geometry measurement system:

| Measurement Items | Scale | Technical Requirement | Remark | ||

| Gauge | 1410-1485mm | Zero point accuracy | ±0.15mm | Applicable for static measurement | |

| Indication error | ±0.5mm | Applicable for track line measurement | |||

| Repeatability | ±0.375mm | ||||

| Gauge change rate | Max. tolerance | ±0.03% | Applicable for track line measurement | ||

| Repeatability | ≤0.045% | ||||

| Cant (superelevation) | ±225mm | Max. tolerance | ±0.5mm | Applicable for static or track line | |

| Turning error | ≤0.3mm | Applicable for static measurement | |||

| Repeatability | ≤0.375mm | Applicable for track line | |||

| Twist | Max. tolerance | ±0.7mm | Applicable for track line | ||

| Repeatability | ≤0.5mm | ||||

| Rail height and direction | ±100mm | Max. tolerance | ±1mm | Applicable for track line | |

| Repeatability | ≤0.75mm | ||||

| Versine | ±400mm | Max. tolerance | ±1mm | Applicable for track line | |

| Repeatability | ≤0.75mm | ||||

| Rail wear | Vignole, grooved rails | ±0.3mm | Applicable for track line | ||

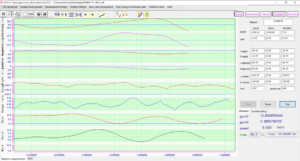

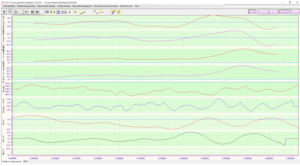

The software provides a graphical interface for real-time observation of the curve changes and numerical display of various detection parameters, provides over limit alarm, and supports data playback, parameter configuration, image scaling, movement, report exporting and other functions, making the operation easy and simple.

Job inspection interface

Data playback interface

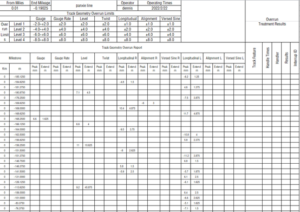

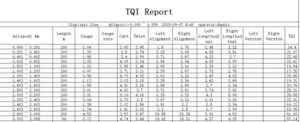

The software provides various report formats, including over limit reports, TQI reports, summary reports, kilometer summary reports, curve reports, defect reports, etc. The following are some examples of these reports.

Over limit report

TQI Report

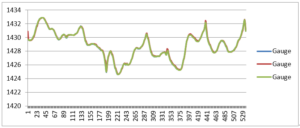

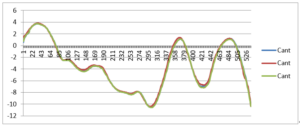

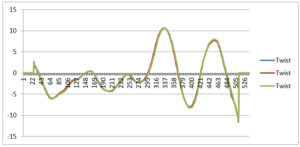

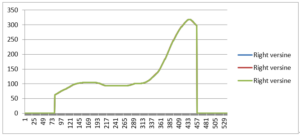

For the convenience of users in conducting repetitive analysis of data, the software provides CSV format for the generated data, which can be opened using tools such as Excel for comparative analysis of multiple sets of data. The following is an example for comparison of the consistency of three actual test data (including round trip):

Gauge

Cant

Twist (6.25m basic length)

Versine

The repeatability of cant and twist reached 98.6%, and the repeatability of other detection parameters reached over 99%, meeting the requirements of various indicators for Level I track geometry measurement system.