Product Details:

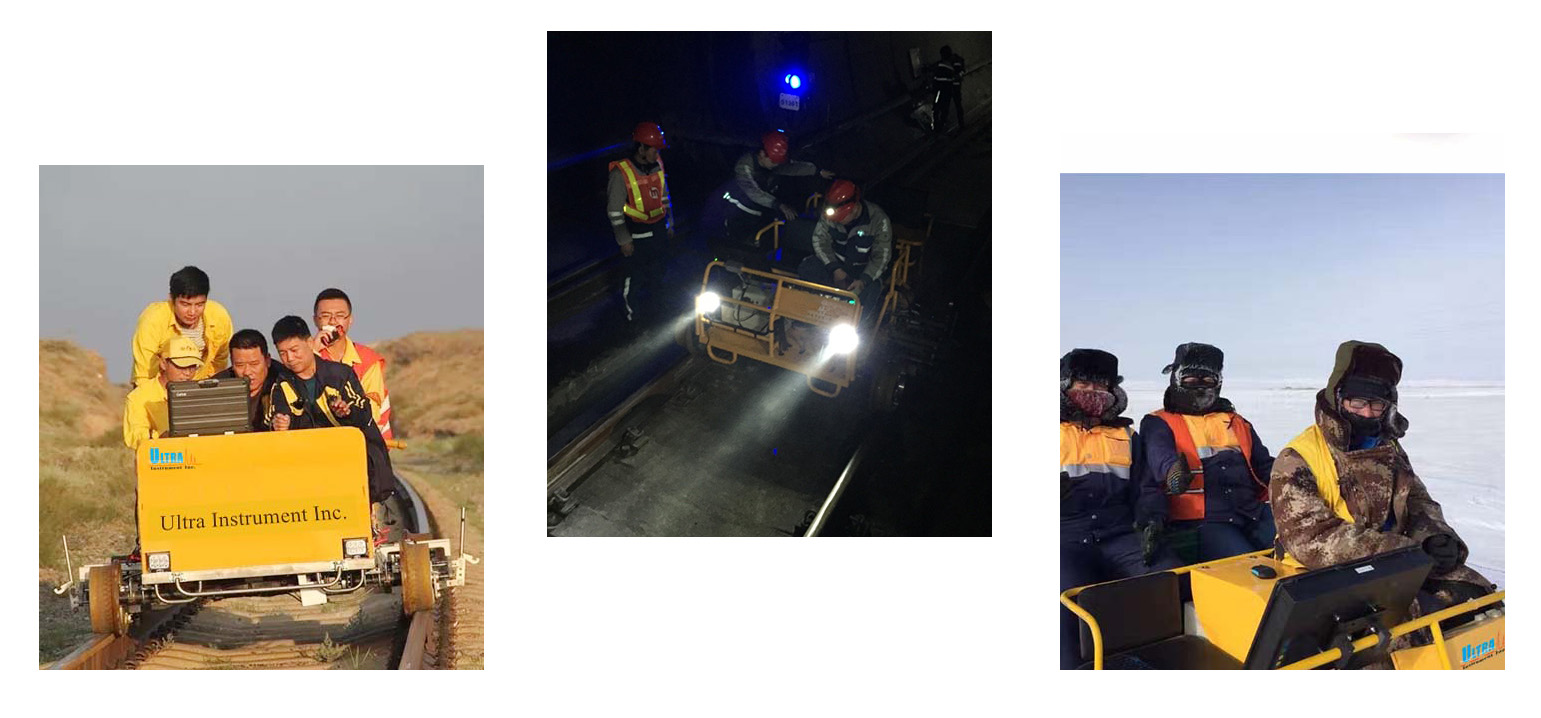

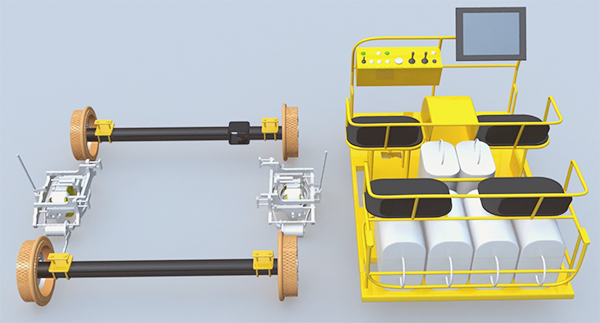

UR18-D ultrasonic rail flaw detection vehicle uses lithium battery drive, patented disassembled structure design. As a result, only two people can carry every module. The travel speed of the vehicle is 20km/h, the detection speed is 15km/h. This automatic ultrasonic testing vehicle is suitable in different railroad, such as state-owned railways, private railways, ports, mineral company track and also city metro.

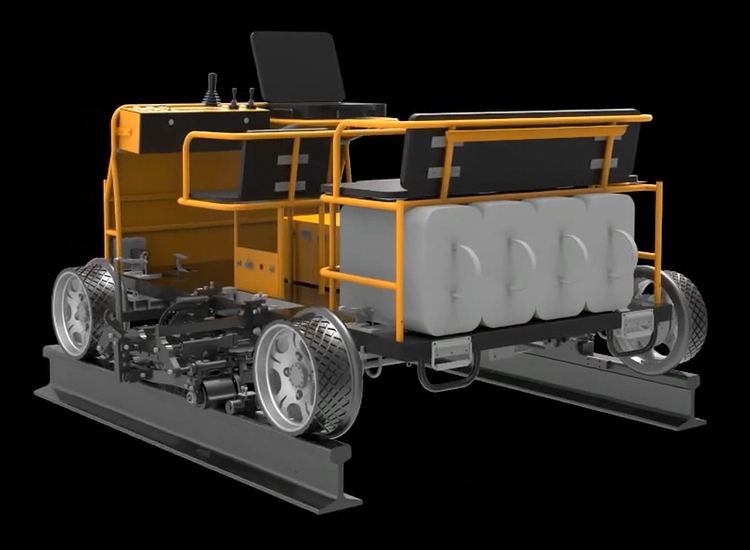

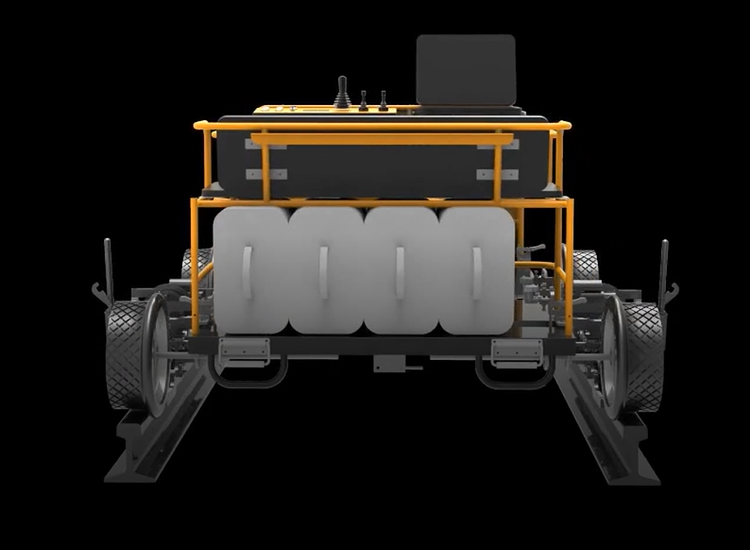

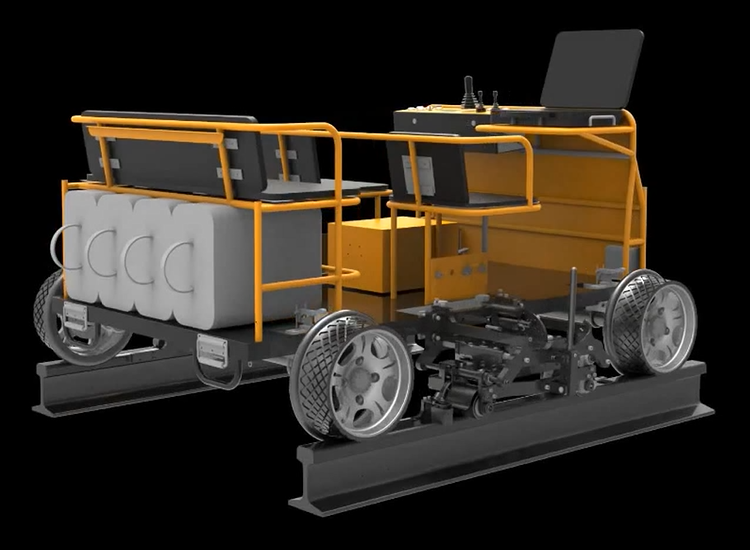

System Components

- The dual-rail ultrasonic rail flaw detection vehicle contains probe, instrument, probe centering mechanism, walking platform and auxiliary device.

- The running platform consists of the vehicle body, walking wheel, transmission device, brake device and power supply, etc.

- The auxiliary device contains safety protection devices, lighting devices, meters and coupled water tank.

Technological Requirement

- The primary and secondary waves is to detect transverse cracks of the rail head.

- Overall components facilitate the adjustment and maintenance of all parts. with a lightweight, modular design, a single module not exceeding 60kg, and total weight exceeding 240kg (excluding battery and coupled water), and assembly or lower disassembly within 5 minutes.

- Running operation and detection system can be controlled independently, can drive in two directions.

- Maxim driving speed: not less than 20km/h.

- Maxim constantly detecting speed: no less than 15km/h.

- Endurance: not less than 60km or 4h by constantly work.

- Mileage positioning accuracy error: less than 5‰.

- Loading capacity:not less than 460kg,can load 4 people.

- Equipped with no less than 100L coupled water tank, the water volume is visual.

Safety Performance Requirement

- Safety belt, horn, windshield, lights, stone sweeper, anti-overturning device and other safety protection devices.

- The luminance at 50m is not less than 2lx to meet the needs of night work.

- All instruments are complete, with speed, power, warning and other information display, visible at night.

Main Features:

Disassembld Structure

The UR18-D ultrasonic rail flaw detection vehicle platform is disassembled, as a result, only two persons necessary to carry each part, and the weight of each part is less than 48kg, so this feature makes operation easier.

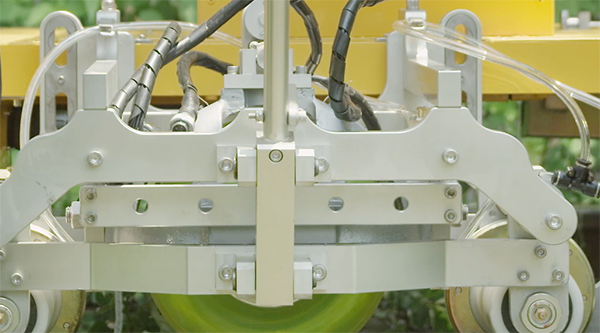

Non-Destructive Detection Wheel

The rail flaw detection vehicle uses 9-channel wheel probe, the normal operation at a maximum speed of 15km/h; and the wheel holder can control the position and the angle automatically. The angles can be adjusted by the operator through the console, in a word, this centring system is flexible and reliable, without loosening and blocking a lttile.

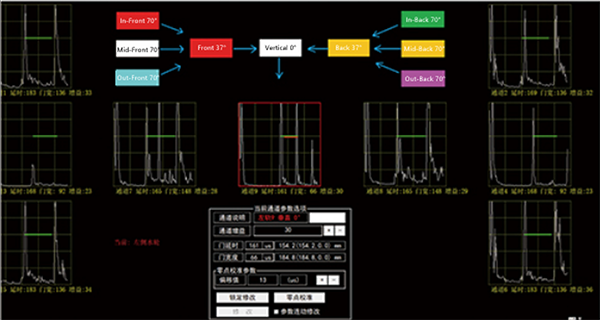

Software System

The main menu of the detection program includes major items including A scan, B scan, and management items. Data management computer system (or software) can record, playback, and transfer job information (unit, personnel, time, line name, line, and mileage), speed, sensitivity, and A/B type data, etc.

A-Scan interface

A-Scan interface

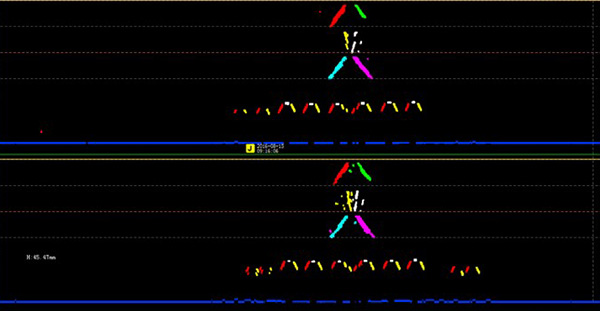

B-Scan Interface

B-Scan interface

… …

Check the video of UR18-D ultrasonic rail flaw detection vehicle here, or you can contact us directly for more product details !