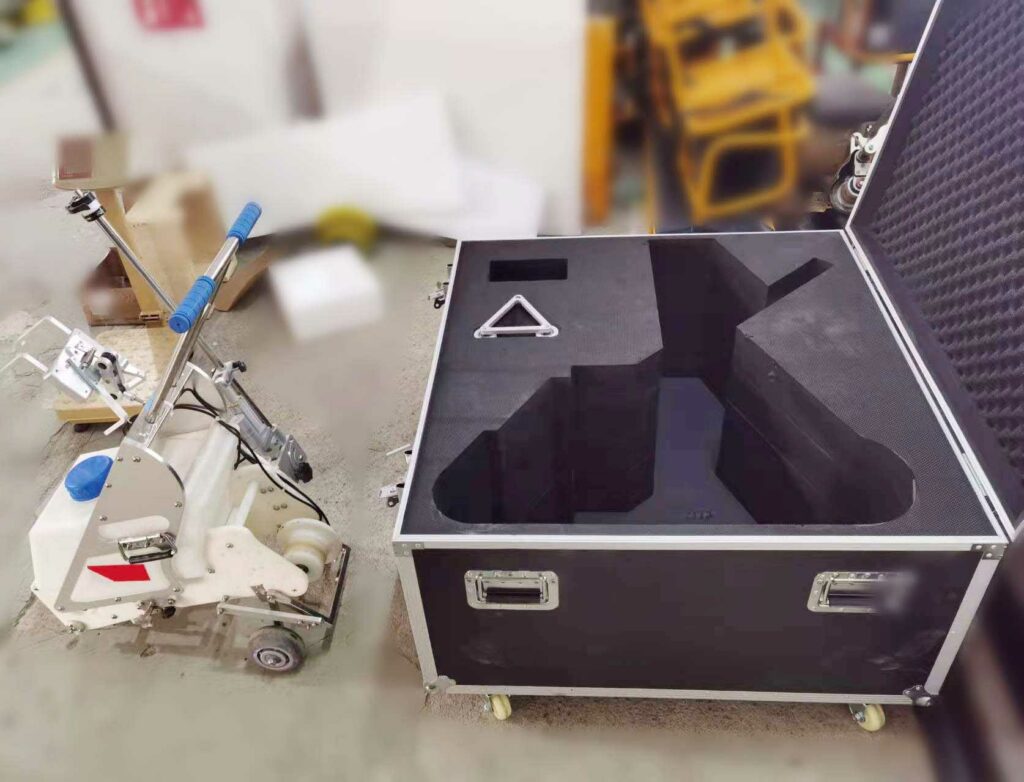

The portable RT10-C rail flaw detection hand push cart sent to Korean customers this time is an upgraded product. We have made all-round updates in terms of detection head and frame. We have made appropriate upgrade and adjustment in terms of flaw detection performance, and optimized the frame structure, which is more convenient to use and more compact in appearance. At the same time, we have customized the box packaging for this equipment, using high-quality sponge lining, which is completely cut according to the product food, which is less easy to wear during transportation, and provides a better solution for the storage of later customers.

rt10-c rail flaw detection trolley

Main specification of RT10-C Rail Flaw Detection Hand Push Cart.

Main Processor: 500MHz

Channels: 10 channels, in which nine channels are used for scanning of the rail, one channel is used for hand verification of defect in hand test mode.

Test mode: simultaneous A-scan and B-scan.

Frequency Range: 2~4MHz

Repetition Rate: Driven by encoder, 3mm/pulse

Pulser: 520V negative spike

Detection Range: Applicable to 90~145lb Rail

Testing Speed: up to 5km/hour

Gain Range: 0~80dB in 1dB step

Alarm: Threshold level adjustable, slope line detection

Data file recording range: 200 miles, selectable up to 400 miles

Battery: Lithium 14.4V, 10.0 ampere hour up to 9 hours. Recharge time 4 hours

Charger: 100~240VAC, 50~60Hz

Display: Amorphous silicon TFT LCD panel with LED, 8.4 inch diagonal, 800×600 resolution, high brightness.

GPS: Differential GPS, 1Hz, < 5 meter.

Temperature Range: Operating -30oC ~ 80oC (-22°F~176°F),

Storage :-40oC ~ 85oC (-40°F~185°F),

Size: 330x240x220mm (13×9.4×8.5inch)

Weight(including battery): 4kg ( 9lb)